Ramsay MultiCraft & Electrical Maintenance Test Prep Guide [2025]

Ramsay MultiCraft & Electrical Maintenance Test Prep Guide [2025]

The Ramsay Test is a key hurdle for anyone pursuing roles in maintenance, engineering, or multicraft positions. Trusted by employers to assess mechanical aptitude, electrical knowledge, and troubleshooting skills, this test can determine whether you land that dream job or miss the mark. But with the right preparation, success is within your reach.

Whether you're a seasoned professional looking to refresh your knowledge or transitioning into a technical role for the first time, this guide will equip you with the tools to ace the test and stand out in your career.

Let’s dive in and take the first step toward achieving your goals!

Comprehensive Overview of the Ramsay MultiCraft Test

What is the Ramsay MultiCraft Test?

The Ramsay MultiCraft Test evaluates the technical skills required for maintenance roles in industrial and manufacturing settings. By covering both mechanical and electrical concepts, the test measures your ability to perform a variety of maintenance and repair tasks.

Who Should Take It?

- Maintenance Technicians

- Electricians

- Mechanics

- Other technical professionals in industrial environments

Test Format and Purpose

- Format: Multiple-choice questions assessing your expertise in mechanical, electrical, and diagnostic tasks.

- Duration: Typically 60 minutes.

- Purpose: To confirm your problem-solving abilities, technical knowledge, and hands-on skills for MultiCraft roles.

Key Focus Areas for Preparation

The Ramsay Multicraft Test assesses knowledge across various mechanical and electrical domains, essential for industrial maintenance and troubleshooting. The topics can be grouped into three major categories based on their practical applications:

1. Mechanical Systems and Power Transmission

Understanding mechanical movement and power transfer is crucial for industrial machinery. This includes the operation of hydraulic and pneumatic systems, covering their components such as pumps, valves, and actuators, along with troubleshooting efficiency issues like leaks and pressure loss.

Additionally, power transmission mechanisms such as gears, belts, chains, and couplings play a key role in ensuring machinery functions efficiently.

Proper lubrication methods are also essential to minimize wear, prevent contamination, and maintain smooth system performance.

2. Fabrication, Assembly, and Structural Safety

A critical part of multicraft skills involves welding and rigging, which includes different welding techniques like MIG, TIG, and arc welding, as well as safe material handling through lifting techniques, hoists, and slings.

Alongside fabrication, shop tools and equipment such as lathes, drills, and hand tools are necessary for precise machining and assembly.

Safety procedures—including the use of personal protective equipment (PPE), fire hazard prevention, and proper ventilation—are essential to maintain a secure working environment.

3. System Operation, Maintenance, and Troubleshooting

Effective system maintenance ensures longevity and efficiency in industrial settings. This section covers pumps and piping systems, detailing different pump types (centrifugal, diaphragm, and positive displacement) and the selection of appropriate piping materials based on pressure and environmental considerations.

Furthermore, combustion principles are essential for understanding the operation of burners, ignition systems, and fuel types used in industrial applications. Maintenance strategies for these systems focus on alignment, fasteners, and preventative inspections to reduce downtime and optimize performance.

Ace the Ramsay Test & Unlock Better Opportunities

The Ramsay Test can be tough, but you don’t have to face it alone. Our proven prep pack gives you:

✅ Comprehensive tutorials to master every section

✅ Realistic practice tests to simulate exam conditions

✅ Expert strategies to help you succeed on your first try

Don’t leave your future to chance—prepare with the best and maximize your score!

Detailed Section Breakdown

Welding and Rigging

- Welding Techniques: Arc welding, MIG, TIG, and oxy-fuel welding

- Rigging Principles: Safe lifting techniques, hoists, and slings

- Safety Procedures: PPE requirements, fire hazards, and ventilation

Power Transmission, Lubrication, Mechanical Maintenance, and Shop Machines, Tools, and Equipment

- Power Transmission: Gears, belts, chains, and couplings

- Lubrication Methods: Greasing techniques, oil types, and contamination prevention

- Mechanical Maintenance: Bearings, alignment, and fasteners

- Shop Equipment and Tools: Lathes, mills, drills, and hand tools

Motors, Control Circuits, Schematics, and Print Reading

- Electric Motors: AC and DC motor operation and maintenance

- Control Circuits: Starters, relays, and variable frequency drives (VFDs)

- Schematics and Print Reading: Electrical symbols, wiring diagrams, and ladder logic

Digital Electronics, Power Supplies, Computers, PLC, and Test Instruments

- Digital Electronics: Logic gates, microprocessors, and digital signals

- Power Supplies: AC/DC converters, transformers, and rectifiers

- Programmable Logic Controllers (PLCs): Inputs, outputs, and ladder logic programming

- Test Instruments: Multimeters, oscilloscopes, and signal analyzers

Basic AC and DC Theory, Power Distribution, and Electrical Maintenance

- AC/DC Theory: Voltage, current, resistance, and circuit analysis

- Power Distribution: Transformers, circuit breakers, and load balancing

- Electrical Maintenance: Troubleshooting wiring, grounding, and system faults

Advanced Topics to Master

Hydraulics and Pneumatics

- Fluid Power Systems: Understanding hydraulic and pneumatic systems

- Components and Operation: Valves, actuators, pumps, and compressors

- Troubleshooting and Maintenance: Identifying leaks, pressure loss, and efficiency issues

Pumps, Piping, and Combustion

- Pump Types and Operation: Centrifugal, diaphragm, and positive displacement pumps

- Piping Systems: Pipe materials, fittings, and pressure considerations

- Combustion Principles: Fuel types, burners, and ignition systems

Practical Examples and Case Studies

Tools, Materials, and Equipment

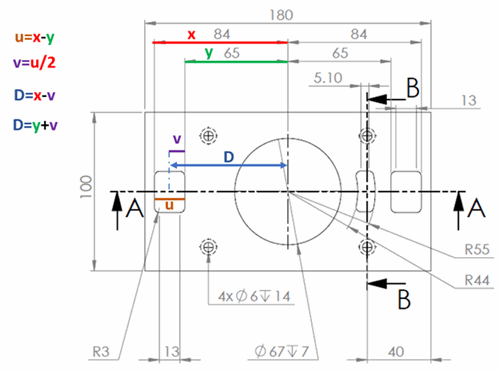

Tools, Materials, and Equipment Sample Question

What is the value shown on the micrometer?

Print Reading - Mechanical

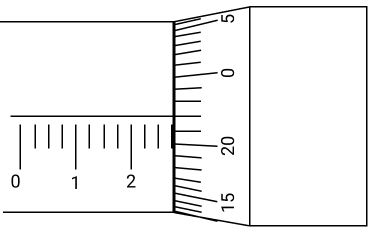

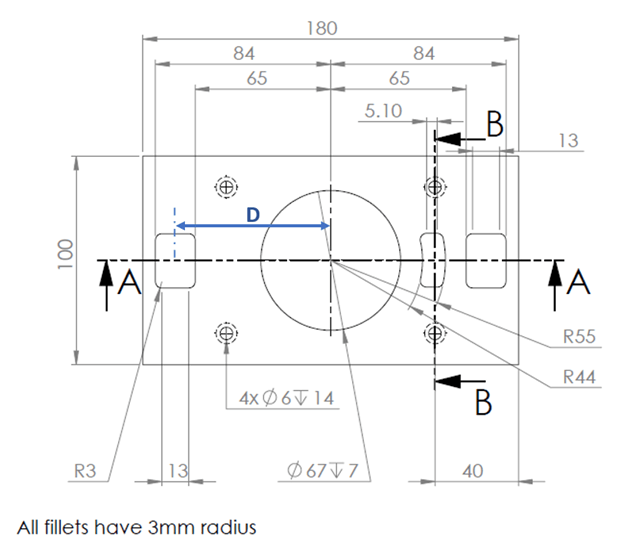

Print Reading - Mechanical Sample Question

What is D in the above drawing?

Hydraulics and Pneumatics

Hydraulics and Pneumatics Sample Question

Test Strategies

- Focus on time management: Allocate more time to complex sections like troubleshooting.

- Practice with PLC test questions Ramsay resources.

- Study guides tailored to electrical maintenance test practice are invaluable.

Master the Ramsay Test & Secure Your Future

Passing the Ramsay Test—especially the Ramsay Multicraft exam—requires strong mechanical aptitude, electrical maintenance knowledge, and problem-solving under pressure.

With our expert-designed prep pack, you’ll get comprehensive tutorials, practice tests, and proven strategies to boost your confidence and maximize your score.

Join hundreds of successful test-takers who improved their scores and landed high-paying roles.